| Tel | : | +90 216 392 52 13 Pbx | |

| : | +90 533 667 61 07 GSM | ||

| Fax | : | +90 216 392 19 44 | |

| : | info@tellus-cme.com |

BRICK - TILE

In general, brick making process is divided to three processes:

1) clay preparation and forming

2) drying

3) firing

Machinery and equipment of these units must be chosen by taking into consideration physical and chemical qualities of the raw material. This decision has a direct affect on cost and quality of the final product. TELLUS supplies and manufactures machinery and equipment according to this principle and provides complete technical service.

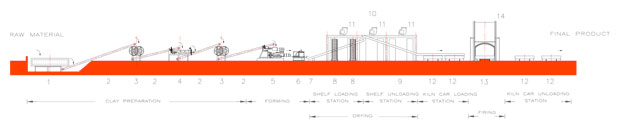

TYPICAL PRODUCTION FLOW OF A BRICK PLANT

On the brick plant designed by TELLUS, raw material loaded to box feeder [1] carries through conveyor belt [2] to first grinding mill [3], batch mixer [4], second grinding mill [3], de-airing pug mill [5] and brick cutter [6] respectively and goes out as unfired or green bricks.

Formed bricks are transferred to loading station with sloped belt [7] and are loaded to drying shelves [8] to be sent to tunnel drier [12].

When a drying shelf loaded with green brick enters to drier, another drying shelf full of dried bricks on the other end moves out and returns to the loading / unloading station. Dried bricks that arrives to loading station is loaded to kiln cars [16] and stocks up at the entrance of the kiln.

Kiln cars full of dried bricks enters to tunnel kiln[17] with intermittent intervals; passes through tunnel kiln which is set to firing temperature; comes out and are transferred to unloading and packaging station [18]. In this station, bricks are unloaded from kiln cars and packed up to be ready for sale.

1) clay preparation and forming

2) drying

3) firing

Machinery and equipment of these units must be chosen by taking into consideration physical and chemical qualities of the raw material. This decision has a direct affect on cost and quality of the final product. TELLUS supplies and manufactures machinery and equipment according to this principle and provides complete technical service.

TYPICAL PRODUCTION FLOW OF A BRICK PLANT

On the brick plant designed by TELLUS, raw material loaded to box feeder [1] carries through conveyor belt [2] to first grinding mill [3], batch mixer [4], second grinding mill [3], de-airing pug mill [5] and brick cutter [6] respectively and goes out as unfired or green bricks.

Formed bricks are transferred to loading station with sloped belt [7] and are loaded to drying shelves [8] to be sent to tunnel drier [12].

When a drying shelf loaded with green brick enters to drier, another drying shelf full of dried bricks on the other end moves out and returns to the loading / unloading station. Dried bricks that arrives to loading station is loaded to kiln cars [16] and stocks up at the entrance of the kiln.

Kiln cars full of dried bricks enters to tunnel kiln[17] with intermittent intervals; passes through tunnel kiln which is set to firing temperature; comes out and are transferred to unloading and packaging station [18]. In this station, bricks are unloaded from kiln cars and packed up to be ready for sale.